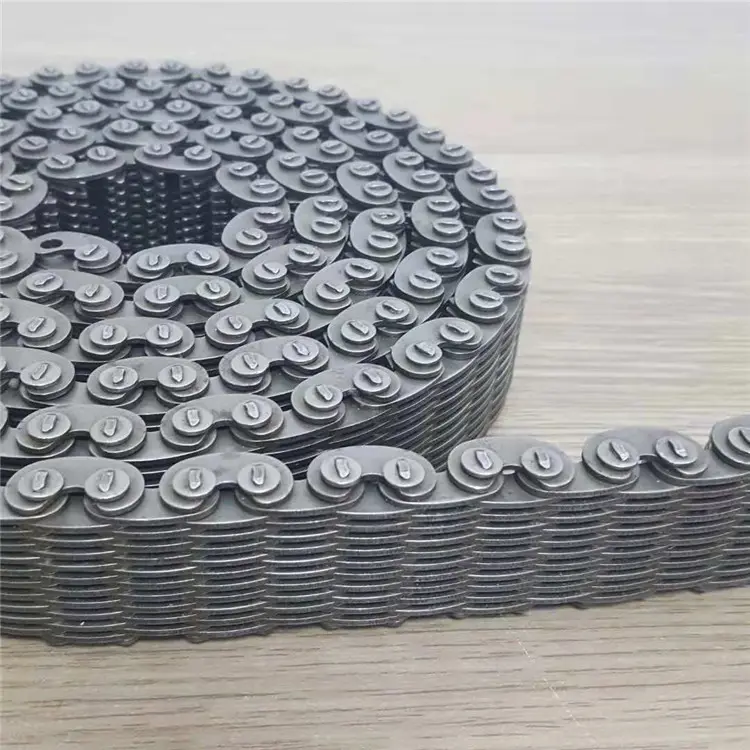

Product Description

| 1)Type | roller chain |

| 2)Materials | steel: 40Mn(Plate) 30CrMnTi(Pin) 20Mn(Bush) Mn10(Roller) 65Mn(Clip) |

| 3)Chain No. | 420h/428h/520h/525h/530h |

| 4)Lifetime | 30000 KMs |

| 5)Function | transmission chain |

| 6)MOQ | 100meters |

| 7)Supply Ability | 100000 Meter/Meters per year |

| 8)Tensile Strength | standard |

| 9)Delivery Time | within 30 days after receiving your 30% deposits |

| 10)Payment Terms | 30%deposit and balanced by L/C,T/T |

| 11)Packing | chains packing in polybag and color box, also can packing as your requirement |

Our Services

Pre-sales:

1. OEM &ODM service

2. Any of your kind inquiry would be replied within 24 hours.

3. Complete product information will be offered

4. Free sample will be sent if you need .

5. Any other reasonable requirements as per requested

During production ,we provide:

1. Schedule of production

2. Mass production picture will offered

3. Any other reasonable requirements as per requested

Finish production:

1. Courier tracking number

2. Documents you need

3. Protection of your sales area, ideas of design and all your private information.

FAQ:

Q1: Do you inspect the finished products?

A: Yes, each step of production and finished products will be carried out inspection by QC departing before shipping.

Q2: What’s the warranty of your products?

A: Usually we guarantee one year after delivery date, but depending on the specified product.

Q3: Are you manufacturer or Trade Company?

A: Both we are. We have been in motorcycle parts for nearly 20 years.

Q4: How to visit factory?

A: Leave us a message, and we will pick you up by car for free.

Q5: Can you do custom logo on the chain?

A: Yes,we can do custom logos by molding. Need your Authorization Letter.

| Type: | Chain |

|---|---|

| Material: | Steel |

| Certification: | ISO9001:2001 |

| Number of Row: | Single Row |

| Surface Treatment: | Sand Blasting, Oiling |

| Transport Package: | Polybag + Color Box + Carton |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can a motor chain be used in vertical motion applications?

Yes, a motor chain can be used in vertical motion applications. Vertical motion refers to applications where the chain is responsible for lifting or lowering loads vertically. Motor chains are commonly used in various vertical motion systems, such as elevators, vertical conveyors, lifting mechanisms, and overhead cranes.

When using a motor chain for vertical motion, it is important to consider the following factors:

1. Load Capacity:

Ensure that the motor chain has sufficient load-carrying capacity to handle the weight of the load being lifted or lowered. It is crucial to select a chain with a suitable working load limit to ensure safe and efficient operation.

2. Tensioning and Alignment:

Proper tensioning and alignment of the motor chain are critical in vertical motion applications. The chain should be adequately tensioned to prevent excessive slack or sag, which can affect its performance and increase the risk of derailment.

3. Safety Mechanisms:

Implement appropriate safety mechanisms, such as limit switches or overload protection devices, to ensure safe operation and prevent accidents in vertical motion applications. These mechanisms help detect and respond to abnormal conditions, such as excessive load or chain tension.

4. Lubrication and Maintenance:

Regular lubrication and maintenance are essential for the proper functioning and longevity of the motor chain in vertical motion applications. Ensure that the chain is properly lubricated to minimize friction and wear.

5. Compliance with Regulations:

Ensure that the motor chain and associated components comply with relevant safety and industry regulations for vertical motion applications. This includes adherence to standards and guidelines for load capacity, materials, design, and installation.

By considering these factors and following proper installation and maintenance practices, a motor chain can be effectively used in vertical motion applications, providing reliable and efficient performance.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

How do you select the right motor chain for a specific motor?

When selecting a motor chain for a specific motor, there are several factors to consider. Here is a step-by-step guide:

1. Determine the motor specifications: Start by understanding the motor’s power rating, speed, and torque requirements. This information will help you choose a motor chain that can handle the motor’s power output and torque demands.

2. Identify the application requirements: Consider the specific application in which the motor will be used. Determine if the motor will be subjected to high loads, high speeds, or harsh environmental conditions. This will help you select a motor chain that is suitable for the application’s demands.

3. Determine the chain type: Motor chains come in various types, including roller chains, silent chains, bush chains, and more. Each chain type has its own characteristics and performance capabilities. Select a chain type that aligns with the requirements of the motor and application.

4. Calculate the chain size: Determine the required chain size based on the motor’s power and torque requirements. Consider factors such as pitch size, roller diameter, and number of chain links. Manufacturers typically provide chain size charts or calculation tools to assist in selecting the right chain size.

5. Consider the environmental factors: Take into account the environmental conditions in which the motor will operate. If the motor is exposed to moisture, chemicals, high temperatures, or other harsh elements, choose a motor chain with appropriate corrosion resistance, temperature resistance, and durability.

6. Consult manufacturer recommendations: Consult the motor manufacturer’s recommendations or specifications to identify any specific requirements or restrictions for motor chains. They may provide guidance on compatible chain types, lubrication requirements, and maintenance recommendations.

7. Evaluate cost and availability: Consider the cost and availability of the selected motor chain. Evaluate factors such as initial cost, maintenance requirements, and the availability of spare parts or replacements.

By considering these factors and conducting thorough research, you can select the right motor chain that matches the motor’s specifications, application requirements, and environmental conditions. It is recommended to consult with motor and chain manufacturers or industry experts for further guidance and assistance.

editor by CX 2023-10-25