Product Description

Company Information

Our factory manufacture laser levels, laser distance meters, power tools, cordless tools and airless paint sprayers. Laser levels include 2 lines, 5 lines, 8 lines, 12 lines and 16 lines with red and green beams. For laser distance meters, we manufacture 30m to 120m range. Our professional power tools include angle grinder, marble cutter, electric drill, impact drill, hammer, demolition hammer, blower, cut-off machine. Besides, we produce full range of power tools armatures and field coils. Cordless tools is our main business also. They are cordless drill with brush motors and brush-less motors, cordless impact drill, cordless wrench, cordless angle grinder, cordless circular saw, cordless hammer and so on. We supply piston sprayers and diaphragm sprayers. Our products pass CE, EMC, RoHs, FCC certificates. We have already exported to many countries and received great feedback. OEM and ODM are provided. We are making great efforts to develop new products to meet different requirements. Products research and development is specially important, and we have been investing a lot of funds. “Never stop improving.” is 1 of our key company culture. We sincerely welcome friends from all over the world to visit our company. Our aim is to establish a long-term business relationship with all our partners.

Our Service

24 hours online service.

Professional sales and technical team standby

One year warranty

OEM and ODM

Ready goods fast delivery

Satisfied quality and better service

FAQ

1.Can I have a sample for testing?

Samples are available. Please send us inquiry and discuss details with our sales team.

2.What is MOQ?

MOQ is 1 piece. For OEM brand, we can discuss the order details.

Our sales team has rich experience and can give quick and satisfied reply.

3.Can I add my brand logo on the products?

Sure, OEM and ODM are available. We can make your own brand package.You can send us inquiry and tell us details.

4.What about inspection procedures?

All our goods are 100% inspected by our QC team understand strict standard. Raw materials must be inspected first. Goods in production are also inspected 1 by one. Finished goods are finally needs to be inspected. Advanced testing equipment are used during the procedures. We can provide inspection reports including goods pictures and video after your order goods finished. 100% quality guaranteed.

5.Can we mix the 20ft container?

Yes,you can purchase different products and fulfill in 1 container. Our sales have rich experience for exporting. We can give you a best transportation way with lowest cost.

6.How about payment terms and how to pay?

For retail products, 100% should be paid. For wholesale order, 30% deposit is paid before production. Rest 70% before shipment, or at the sight of B/L copy.We can accept order in Alibaba. Western Union, Bank T/T transfer, and others. Please discuss details with our sales team.

7.How about after-service?

You need to tell us details of feedback including pictures and video if necessary. Then our sales and technical team will solve your problem immediately. We can send you free parts to repair, also with operating video to support you. We will make you satisfied.

8.Can I have a visit to your factory before the order?

Sure,welcome to visit our factory.Our factory is very near from ZheJiang Xihu (West Lake) Dis. Airport. When you come, please inform us ahead of time. We can pick you up.

9.For any other doubts, please do send us inquiry. We will reply you with full details.

We are looking CHINAMFG to your cooperation. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Cordless Electric Portable Chainsaw: | Cordless Electric Portable Chainsaw |

|---|---|

| Rated Voltage(V~): | 21V |

| Frequency(Hz): | 50 |

| Guide Plate Length: | 10 Inch |

| Chain Speed(M/S): | 6 |

| Qty/Ctns(PCS): | 4 |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

What are the different types of motor chains available?

Motor chains come in various types, each designed to meet specific requirements of different applications. Here are some common types of motor chains:

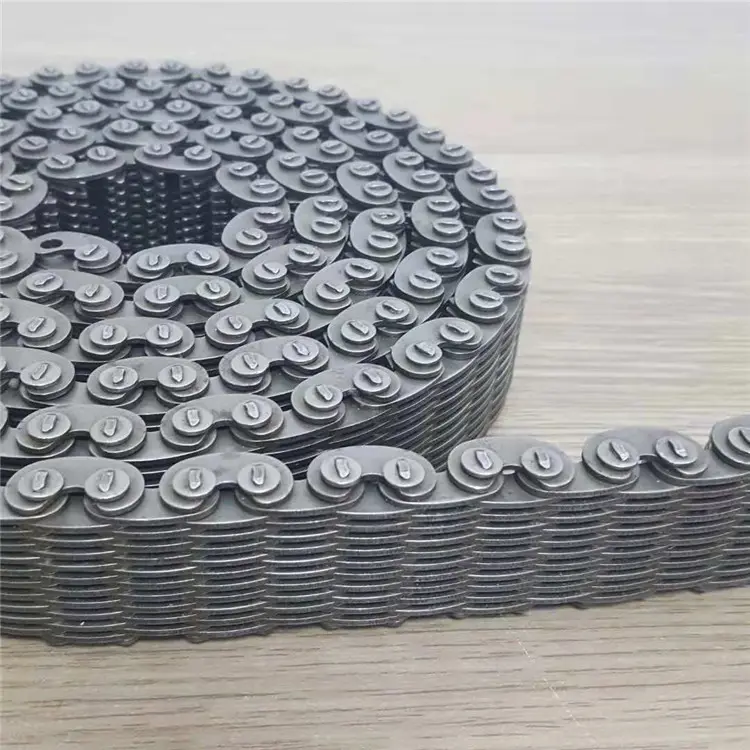

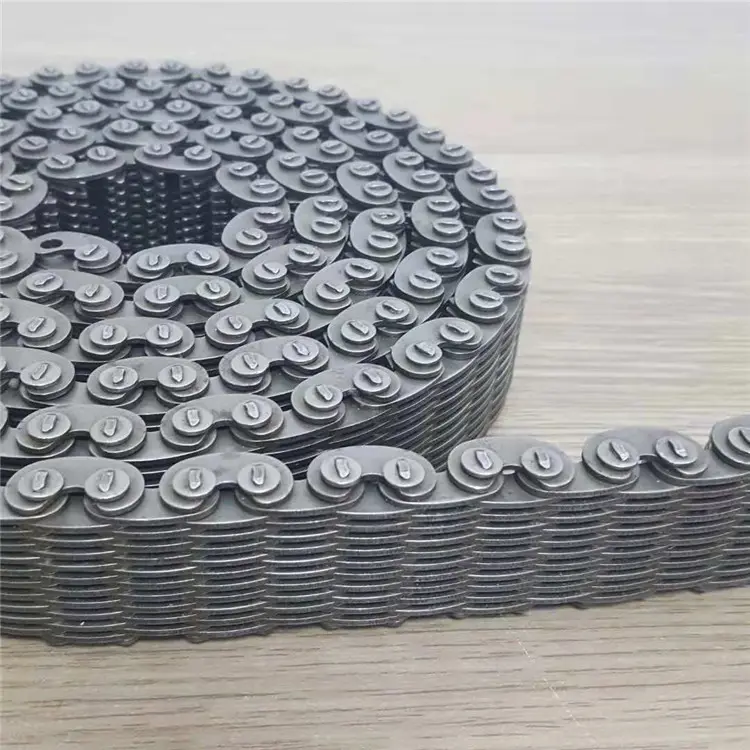

1. Roller Chains: Roller chains are the most common type of motor chain. They consist of inner and outer plates connected by rollers. These chains are known for their high strength, durability, and ability to handle heavy loads. Roller chains are widely used in industries such as automotive, industrial machinery, and agriculture.

2. Silent Chains: Silent chains, also known as inverted-tooth chains, feature tooth-shaped plates that engage with each other. They provide smooth and quiet operation, making them suitable for applications requiring low noise levels. Silent chains are commonly used in precision machinery, printing presses, and automotive timing systems.

3. Leaf Chains: Leaf chains have flat, interlocking plates connected by pins. They are primarily used in lifting and hoisting applications, such as forklifts and cranes. Leaf chains are known for their high tensile strength and resistance to fatigue.

4. Conveyor Chains: Conveyor chains are specifically designed for conveying materials in conveyor systems. They feature large, wide plates to support the load and provide smooth movement. Conveyor chains are used in industries such as mining, food processing, and packaging.

5. Timing Chains: Timing chains are used in engines to synchronize the rotation of the crankshaft and camshaft. They have precise tooth profiles that ensure accurate timing of valve operation. Timing chains are commonly found in automotive engines and other internal combustion engines.

6. Specialty Chains: There are also specialized motor chains designed for specific applications. Examples include escalator chains, bicycle chains, motorcycle chains, and marine chains.

Motor chains are available in different sizes, materials, and configurations to suit specific requirements. It is important to select the appropriate chain type based on factors such as load capacity, speed, environment, and application-specific needs.

editor by CX 2024-04-23