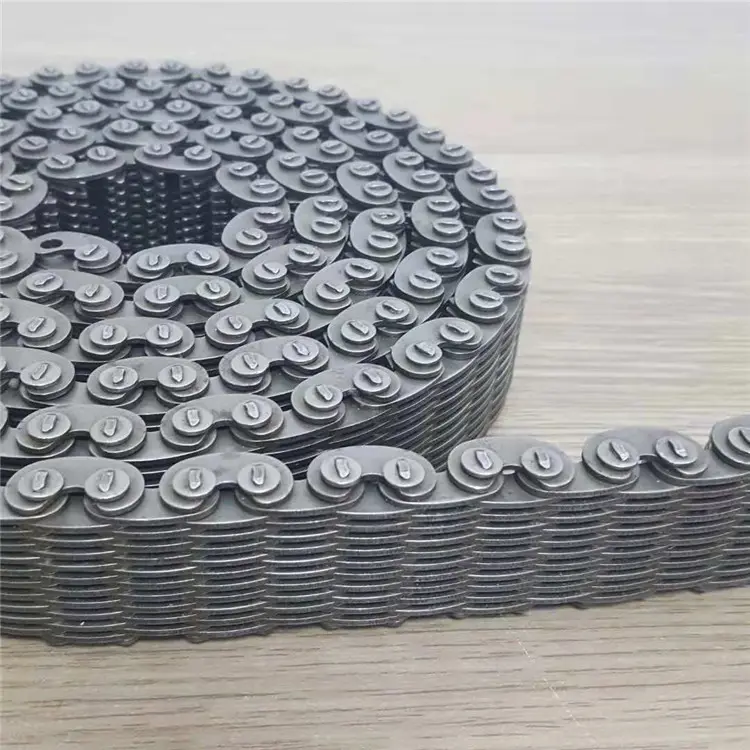

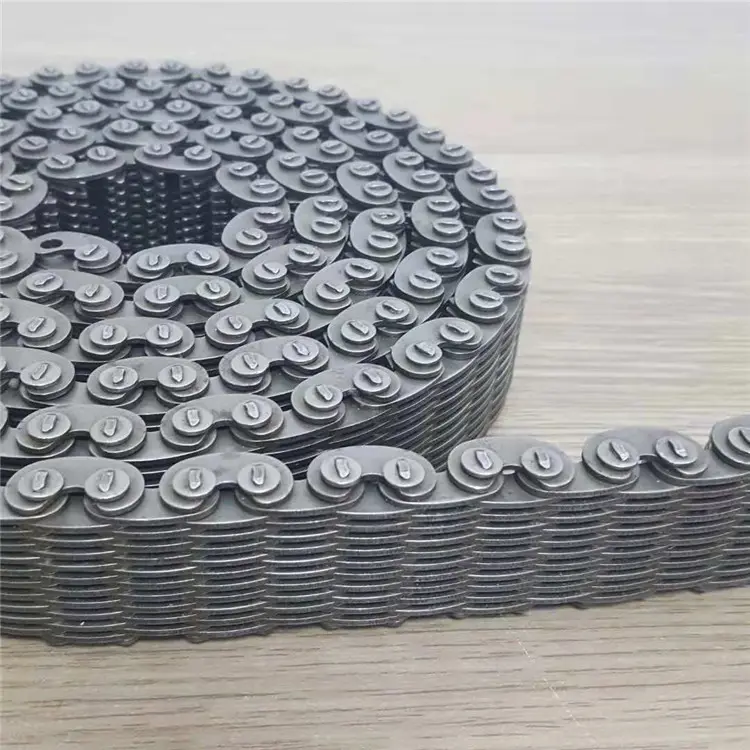

Product Description

Sprocket Kits Auto Chain Custom Motor Industrial Conveyor Photo Paper T8f Tooth Clutch Drum Gear Box Stainless Steel Motorcycle

Manufacturer of Sprocket, Chain sprockets, wheel and sprocket, drive sprocket, sprocket wheel, taper lock sprocket, gear sprocket, idle sprocket, motorcycle sprocket and stainless steel sprocket, can interchange and replace with martin size sprocket, jt size sprockets, did size chain sprocket and so on.

What is Sprocket Kits?

A sprocket kit is a set of sprockets that are used together to transmit power from 1 component to another. Sprocket kits are typically used in motorcycles, bicycles, and other vehicles.

A sprocket kit typically consists of a front sprocket, a rear sprocket, and a chain. The front sprocket is attached to the engine, and the rear sprocket is attached to the rear wheel. The chain connects the front sprocket to the rear sprocket.

The size of the sprockets determines the gear ratio of the vehicle. The gear ratio is the ratio of the number of teeth on the front sprocket to the number of teeth on the rear sprocket. A higher gear ratio will make it easier to accelerate but will reduce top speed. A lower gear ratio will make it more difficult to accelerate but will increase top speed.

Sprocket kits are an important part of many vehicles. They help to transmit power from 1 component to another, and they can be used to control the speed of a vehicle.

Here are some of the benefits of using sprocket kits:

- They are a convenient way to change the gear ratio of a vehicle.

- They are typically more affordable than buying individual sprockets.

- They are often made from high-quality materials that are designed to last.

Here are some of the drawbacks of using sprocket kits:

- They can be more difficult to install than individual sprockets.

- They may not be compatible with all vehicles.

- They can be more expensive than buying individual sprockets.

Overall, sprocket kits are a good choice for people who are looking for a convenient and affordable way to change the gear ratio of their vehicle. They are typically made from high-quality materials that are designed to last.

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Motorcycle, Machinery, Agricultural Machinery, Car |

| Hardness: | Hardened Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

How do you select the right motor chain for a specific motor?

When selecting a motor chain for a specific motor, there are several factors to consider. Here is a step-by-step guide:

1. Determine the motor specifications: Start by understanding the motor’s power rating, speed, and torque requirements. This information will help you choose a motor chain that can handle the motor’s power output and torque demands.

2. Identify the application requirements: Consider the specific application in which the motor will be used. Determine if the motor will be subjected to high loads, high speeds, or harsh environmental conditions. This will help you select a motor chain that is suitable for the application’s demands.

3. Determine the chain type: Motor chains come in various types, including roller chains, silent chains, bush chains, and more. Each chain type has its own characteristics and performance capabilities. Select a chain type that aligns with the requirements of the motor and application.

4. Calculate the chain size: Determine the required chain size based on the motor’s power and torque requirements. Consider factors such as pitch size, roller diameter, and number of chain links. Manufacturers typically provide chain size charts or calculation tools to assist in selecting the right chain size.

5. Consider the environmental factors: Take into account the environmental conditions in which the motor will operate. If the motor is exposed to moisture, chemicals, high temperatures, or other harsh elements, choose a motor chain with appropriate corrosion resistance, temperature resistance, and durability.

6. Consult manufacturer recommendations: Consult the motor manufacturer’s recommendations or specifications to identify any specific requirements or restrictions for motor chains. They may provide guidance on compatible chain types, lubrication requirements, and maintenance recommendations.

7. Evaluate cost and availability: Consider the cost and availability of the selected motor chain. Evaluate factors such as initial cost, maintenance requirements, and the availability of spare parts or replacements.

By considering these factors and conducting thorough research, you can select the right motor chain that matches the motor’s specifications, application requirements, and environmental conditions. It is recommended to consult with motor and chain manufacturers or industry experts for further guidance and assistance.

editor by CX 2023-09-20