Product Description

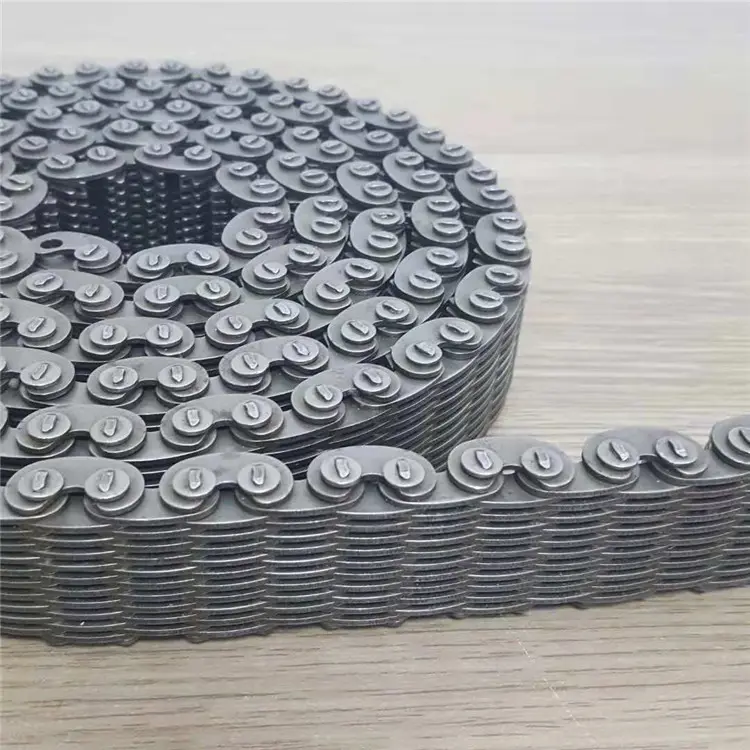

Infiniti/Challenger/Phaeton zhongye/Galaxy Printer Chain/ Tank Chain for Solvent Printer Spare Parts

Printer Compatibility:

Challenger /Infiniti printer :FY-3206HA, FY-3206HF, FY-3206H, FY-3206R, FY-3206G, FY-3276HA, FY-3276R, FY-3208HA, FY-3208HF, FY-3208H, FY-3208G, FY-3208R,3278N

CHINAMFG /Phaeton Printer: UD181LA, UD1812LA, UD211LA, UD2112LA, UD251LA, UD2512LA, UD-181LC, UD-1812LC, UD-211LC, UD-2112LC, UD-2512LC, UD-3212LC; UD-3212LD

Suit — For Roland XC-540 / XC-540mt / XJ-540 / VS-300/ VS-540i/VS- 640/VS- 640i FP-740 / XJ-740 / LEJ-540 LEC-540 / XJ-640 VS-300i / VS-540i / VS-640i / vs-420 / LEC-300 / LEC-300A / LEC-330 / VP-540 / VS-540 / VP-540I / SP-540i

Mimaki CJV300 JV300 printer

| HS Code | 8443992990 |

| Spare Parts Status | In stock |

| Delivery Time | Wthin 2days after payment |

| Delivery Method | Via DHL.FedEx.UPS.TNT.EMS.Sea Shipping.Air Cargo optional |

| Printing Solutions | Technicial Support is available |

| Spare parts Available | All Printer and spare parts are available in Wholsales Price |

| Quality Warranty | 6months for spare parts.12months for machine |

| Payment Way | Bank Transfer.Western Union.MoneyGram.PayPal.Alibaba |

o Solvent Printer, VJ-628,VJ-628X, VJ-1204PLUS,VJ-1324X, VJ-1624X,VJ-1628X, VJ1638X

Flat Bed (UV), VJ 426UF,VJ 1638UH,VJ 1638UR,VJ 1626UH, VJ 1617H

Dye Sublimation Printer,RJ-900X,RJ901,RJ-900c, VJ1624WX, VJ1628WX, VJ1638WX, VJ2638WX

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Professional Technicians |

|---|---|

| Warranty: | 6 Months Warranty |

| Certification: | RoHS, ISO9001, ISO, CE |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

Can a motor chain be used for high-speed applications?

Yes, motor chains can be used for high-speed applications depending on their design and specifications. Here are some factors to consider:

1. Chain Speed Rating: Motor chains are typically rated for specific maximum speeds. It is important to choose a motor chain that has a speed rating suitable for your application. Higher speed ratings indicate that the chain is designed to handle faster rotational speeds without compromising performance or safety.

2. Chain Design: Motor chains for high-speed applications are often designed with features to reduce friction and minimize the effects of centrifugal forces. This may include precision machining, specialized coatings, and optimized lubrication systems. These design considerations help maintain chain stability and performance at high speeds.

3. Lubrication: Proper lubrication is crucial for high-speed motor chain applications. It helps reduce friction, heat, and wear, ensuring smooth operation at elevated speeds. Selecting the appropriate lubricant and establishing a regular lubrication schedule are essential for maximizing the performance and lifespan of the motor chain.

4. Chain Tension: Maintaining proper chain tension is important for high-speed applications. Excessive slack or excessive tension can lead to performance issues, increased wear, and potential chain failure. It is necessary to follow the manufacturer’s guidelines for tensioning the motor chain and regularly check and adjust the tension as needed.

5. Sprocket Design: The design and quality of the sprockets that engage with the motor chain are also crucial for high-speed applications. High-speed sprockets should be precisely machined, balanced, and durable to ensure smooth and reliable power transmission.

It is important to consult the manufacturer’s specifications and guidelines when selecting a motor chain for high-speed applications. They can provide detailed information on the chain’s speed capabilities and any specific considerations for optimal performance at high speeds. By choosing the appropriate motor chain and implementing proper maintenance practices, it is possible to use motor chains effectively in high-speed applications.

How do you select the right motor chain for a specific motor?

When selecting a motor chain for a specific motor, there are several factors to consider. Here is a step-by-step guide:

1. Determine the motor specifications: Start by understanding the motor’s power rating, speed, and torque requirements. This information will help you choose a motor chain that can handle the motor’s power output and torque demands.

2. Identify the application requirements: Consider the specific application in which the motor will be used. Determine if the motor will be subjected to high loads, high speeds, or harsh environmental conditions. This will help you select a motor chain that is suitable for the application’s demands.

3. Determine the chain type: Motor chains come in various types, including roller chains, silent chains, bush chains, and more. Each chain type has its own characteristics and performance capabilities. Select a chain type that aligns with the requirements of the motor and application.

4. Calculate the chain size: Determine the required chain size based on the motor’s power and torque requirements. Consider factors such as pitch size, roller diameter, and number of chain links. Manufacturers typically provide chain size charts or calculation tools to assist in selecting the right chain size.

5. Consider the environmental factors: Take into account the environmental conditions in which the motor will operate. If the motor is exposed to moisture, chemicals, high temperatures, or other harsh elements, choose a motor chain with appropriate corrosion resistance, temperature resistance, and durability.

6. Consult manufacturer recommendations: Consult the motor manufacturer’s recommendations or specifications to identify any specific requirements or restrictions for motor chains. They may provide guidance on compatible chain types, lubrication requirements, and maintenance recommendations.

7. Evaluate cost and availability: Consider the cost and availability of the selected motor chain. Evaluate factors such as initial cost, maintenance requirements, and the availability of spare parts or replacements.

By considering these factors and conducting thorough research, you can select the right motor chain that matches the motor’s specifications, application requirements, and environmental conditions. It is recommended to consult with motor and chain manufacturers or industry experts for further guidance and assistance.

editor by CX 2024-04-22