Product Description

We Have Following Advantages :

1. Self-design and self-produce

2. Factory direct price

3. Keep product upgrading to meet market demand

4. According to customer’s requirements to control costs and also satisfy the design requirements.

5. Small orders welcome

6. Quick shipping within 10 days

| Item No. | CS07 |

| DC voltage | DC21V |

| Rate Power | 1200W |

| Battery | 4.0AH |

| No load speed | 10m/s |

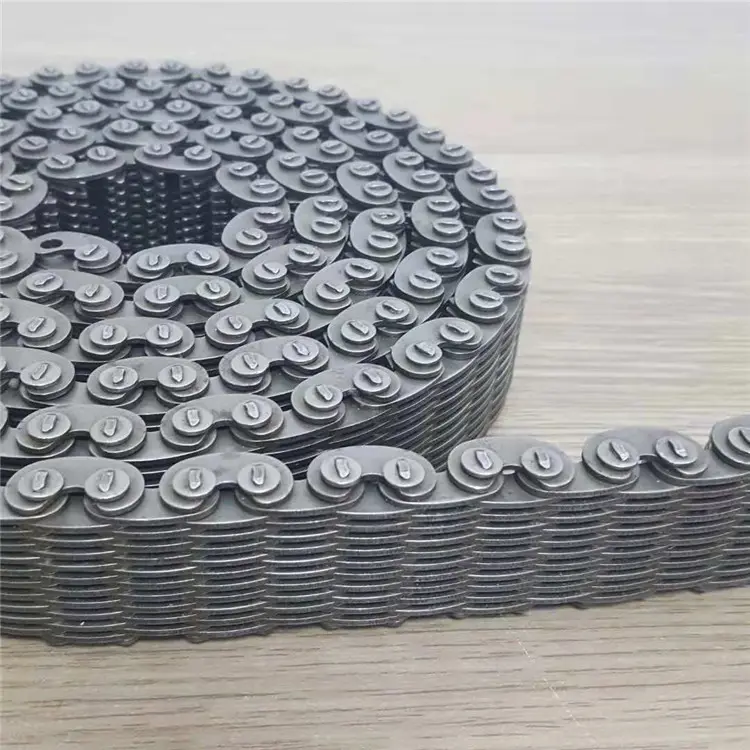

| Bar Length | 5″ and 6″bar and chain |

| Chain Type | 1/4″(6.35) |

| Max. Cutting Length | 100mm |

| Drive Chains Number | 38 pitches |

| Strep spec | 7 gears |

| Machine Size |

445x155x60mm |

| Qty/Ctn | 5pcs |

| Master Carton Size | 53X46X29CM |

| N.W./G.W. | 16/18kgs |

| Motor | Brush less motor/Brush motor |

| 5″ guider bar with | 32 pitches chains |

| 6″ guider bar with | 38 pitches chains |

HangZhou daguo established in 2019, our factory is 1 of the most professional enterprises in China who specialize in developing and producing garden power tools, located in HangZhou, enjoying ease access to ZheJiang and HangZhou cities. We have domestic CHINAMFG power tool accessories suppliers, such as Xihu (West Lake) Dis.cheng, Gribo, has been maintaining a good long term relationship of cooperation. We gain an outstanding reputation for the sophisticated technology, skillful manufacture and excellent quality of the garden tools. With strong R&D capacity, full productive capacity, and OEM capacity, we are capable of providing customers with superior products and the best service!

Though we are a new power tool manufacturer, Daguo is now a first domestic 4″ bar handled chain saw original design and supplier who has been gained state patent since 2571. Here we would like to introduce Mr. Kin, our technical director who graduated from the mechanical design major with a bachelor′s degree. He is particularly good at product appearance design, internal structure research, product practical performance and cost control.

In 2019, the 4-inch small chainsaw designed by KIN caused a big sensation in the current e-commerce environment and garden tools industry, and it is a hot seller and has been selling very well for long time. Many foreign trade companies want to come in as our appointed agents. At present, we also specialized in power tools, garden tools, such as pruning shears, mini chain saw, electrical trimmer and related in China for professional and DIY users worldwide. Here let us highlight 1 of our best selling products as following:

Now our factory has been already from 240 square CHINAMFG to 1000 square meters, as well as the number of employees has increased from 10 to 40, also we have already passed CE/SGS. At the same time, we are adding more and more machinery and equipment, own close to million fixed assets. We have production capacity of 30 million sets yearly. Our enterprise has been chosen as an “first choice of handled chain saw in HangZhou China”, and has several business partners in this industry.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GS, CE, RoHS |

|---|---|

| Condition: | Brand New |

| Type: | Motorized Chainsaw |

| Power: | Electricity |

| Engine Type: | Motor |

| Colour: | Customized |

| Samples: |

US$ 65/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can a motor chain be used in environments with high temperatures or humidity?

Yes, motor chains can be used in environments with high temperatures or humidity, but certain considerations need to be taken into account.

High Temperatures:

When operating in high-temperature environments, it is important to choose a motor chain that can withstand the elevated temperatures. Special heat-resistant materials, such as heat-treated steel or alloys, are often used for the construction of chains intended for high-temperature applications. These materials have superior heat resistance and can maintain their strength and performance even at elevated temperatures.

In addition to selecting the appropriate chain material, proper lubrication becomes even more critical in high-temperature environments. The lubricant used should have a high temperature rating to ensure adequate lubrication and prevent premature wear. Regular monitoring of the chain’s condition and lubrication levels is essential to maintain its performance and minimize the effects of heat.

Humidity:

In humid environments, the risk of corrosion and rust formation on the motor chain increases. To address this, corrosion-resistant materials and coatings are commonly used for motor chains. Stainless steel chains or chains with special corrosion-resistant coatings provide better protection against moisture and humidity.

Proper maintenance and lubrication are also crucial in humid environments to prevent moisture from penetrating the chain and causing corrosion. Regular inspections, cleaning, and lubrication with corrosion-inhibiting lubricants can help extend the lifespan of the chain and maintain its performance.

It is important to note that while motor chains can be used in high-temperature or humid environments, their performance and lifespan can still be affected. It is recommended to consult the chain manufacturer for specific guidelines and recommendations regarding the use of motor chains in such conditions. Additionally, proper ventilation and environmental controls should be considered to minimize the impact of high temperatures or humidity on the chain’s performance.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

How does a motor chain differ from a regular chain?

A motor chain, also known as a power transmission chain, differs from a regular chain in terms of its design and purpose. Here are the key differences:

1. Load Capacity: Motor chains are specifically designed to handle higher loads compared to regular chains. They are built to transmit power and motion between different components in mechanical systems.

2. Precision and Accuracy: Motor chains often have precise tooth profiles or roller systems that ensure accurate positioning and synchronization of components. This is important in applications such as engines, where precise timing is critical.

3. Durability and Strength: Motor chains are built to withstand heavy loads, high speeds, and continuous operation. They are constructed using high-quality materials and advanced manufacturing techniques to ensure durability and strength.

4. Lubrication and Maintenance: Motor chains may require specific lubrication to reduce friction and wear, ensuring smooth operation. Regular maintenance, such as periodic inspection and lubrication, is important to keep the chain in optimal condition.

5. Application-Specific Design: Motor chains are designed for specific applications, such as power transmission in engines, conveyor systems, or lifting equipment. They are engineered to meet the unique requirements of these applications, considering factors such as load capacity, speed, environment, and operational conditions.

It’s important to note that while motor chains are designed for specific applications, they may have similarities with regular chains in terms of basic construction and functionality. However, motor chains are engineered to handle higher loads, provide precise motion transmission, and ensure reliable performance in demanding industrial settings.

editor by CX 2024-05-08