Product Description

We Have Following Advantages :

1. Self-design and self-produce

2. Factory direct price

3. Keep product upgrading to meet market demand

4. According to customer’s requirements to control costs and also satisfy the design requirements.

5. Small orders welcome

6. Quick shipping within 10 days

Product Specification

| Item No. | CS01 |

| DC voltage | 24V |

| Battery | 1.5-4.0Ah |

| No load speed | 6m/s |

| Bar Length | 4″ bar and chain |

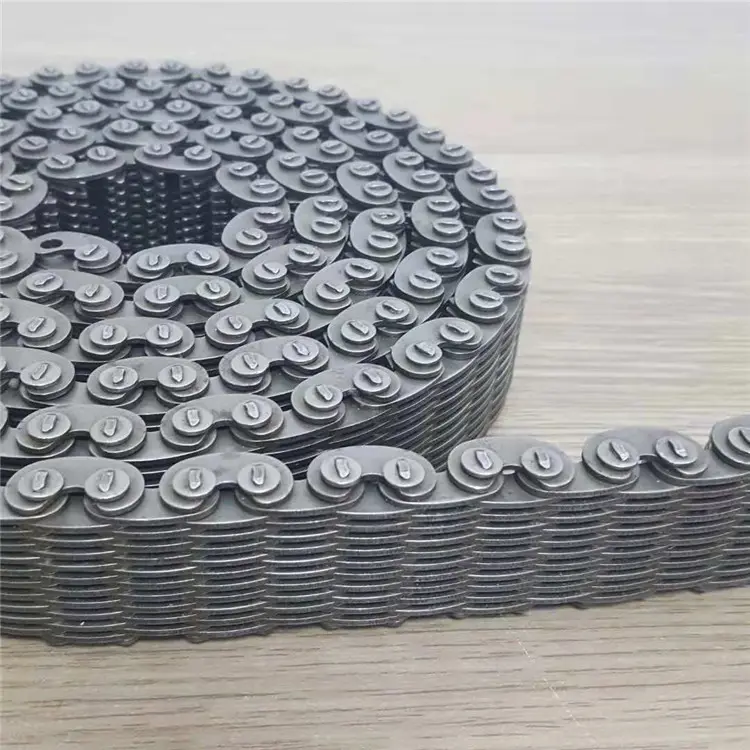

| Chain Type | 1/4″(6.35) |

| Max. Cutting Length | 100mm |

| Qty/Ctn | 6pcs |

| Carton Size | 365mm*330mm*285mm |

| N.W./G.W. | 11/12kgs |

| 20′ | 5200pcs |

| 40′ | 11600pcs |

| 40’HC | 13600pcs |

Main Features

- High Quality and Efficient – This chain saw adapt high-quality guide chain which has undergone a deep quenching process ensures smooth cutting. The wood tooth design can make the chain saw stuck on the branch, cutting efficiency is higher and faster.

- Easy Operation – This mini chainsaw weight just about 0.7kg and a total length of only 33cm (13inch). Most of the people can easily control and use it, and will not be tired from being too heavy.

- Xihu (West Lake) Dis.nized Design – The integrated guide plate dissipates heat quickly and is very resistant to falling and abrasion. With non-slip handle design, the grip is very comfortable. The chain saw switch can adjust the speed according to the strength, and you can adjust the cutting speed you need according to the operating conditions.

- Efficient Cutting – Power Chain Saws takes about 10 seconds to cut a log with a diameter of 10cm (the specific value varies with the actual size and hardness of the wood). This electric saw is very suitable for trees branches pruning, gardening.Note that it is not suitable for sawing dry planks and wood that is too large

- Easy installation – Just install in a few steps. 1, Install the chain into the guide plate, then install them to chainsaw body. 2, Install the side cover and tighten the nut. 3, Use the wrench in the package to turn the screw to adjust the tightness. Just need 1 Minute for all Install.

HangZhou daguo established in 2019, our factory is 1 of the most professional enterprises in China who specialize in developing and producing garden power tools, located in HangZhou, enjoying ease access to ZheJiang and HangZhou cities. We have domestic CZPT power tool accessories suppliers, such as Xihu (West Lake) Dis.cheng, Gribo, has been maintaining a good long term relationship of cooperation. We gain an outstanding reputation for the sophisticated technology, skillful manufacture and excellent quality of the garden tools. With strong R&D capacity, full productive capacity, and OEM capacity, we are capable of providing customers with superior products and the best service!

Though we are a new power tool manufacturer, Daguo is now a first domestic 4″ bar handled chain saw original design and supplier who has been gained state patent since 2571. Here we would like to introduce Mr. Kin, our technical director who graduated from the mechanical design major with a bachelor′s degree. He is particularly good at product appearance design, internal structure research, product practical performance and cost control.

In 2019, the 4-inch small chainsaw designed by KIN caused a big sensation in the current e-commerce environment and garden tools industry, and it is a hot seller and has been selling very well for long time. Many foreign trade companies want to come in as our appointed agents. At present, we also specialized in power tools, garden tools, such as pruning shears, mini chain saw, electrical trimmer and related in China for professional and DIY users worldwide. Here let us highlight 1 of our best selling products as following:

Now our factory has been already from 240 square CZPT to 1000 square meters, as well as the number of employees has increased from 10 to 40, also we have already passed CE/SGS. At the same time, we are adding more and more machinery and equipment, own close to million fixed assets. We have production capacity of 30 million sets yearly. Our enterprise has been chosen as an “first choice of handled chain saw in HangZhou China”, and has several business partners in this industry.

FAQ

- Customer Questions & Answers

- Q:Are you manufacture?

- A:We are original self-design and self-produce.

- Q: What’s your MOQ?

- A: Our MOQ is 1000 units per model for GTL/OEM brand.

- Q: What’s your payment terms?

- A: We could accept L/C sight, T/T and Paypal.

- Q: What’s the delivery time?

- A: We could deliver the goods within 60 days after order confirmed.

- Q: Is the price on this page your final price?

- A: The price on this page is only for your reference. We hope you can inquiry the bottom price based on your quantity. We also have promotion season and will give discount for new customer.

- Q: How about sample buying?

- A: Yes, we could provide samples and deliver with freight collected.

| Standard: | CE |

|---|---|

| Condition: | Brand New |

| Type: | Motorized Chainsaw |

| Power: | Electricity |

| Engine Type: | Motor |

| Chain Material: | Stainless Steel |

| Samples: |

US$ 24/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

What are the advantages of using a motor chain in power transmission?

Using a motor chain in power transmission offers several advantages:

1. High Efficiency: Motor chains are designed to transmit power efficiently from the motor to the driven equipment. They minimize energy losses and ensure maximum power transfer, resulting in high overall system efficiency.

2. Reliable Power Transmission: Motor chains provide a reliable means of transmitting power in various applications. They have high load-bearing capabilities and can handle both high torque and high-speed operations, making them suitable for a wide range of industrial processes.

3. Compact Design: Motor chains have a compact design, which allows for efficient power transmission in tight spaces. They can be easily integrated into machinery and equipment without occupying excessive space.

4. Precise Speed Control: Motor chains enable precise speed control of the driven equipment. By selecting the appropriate chain size and gear ratio, you can achieve the desired speed and maintain consistent operation, essential in applications that require precise motion control.

5. Versatility: Motor chains are versatile and can be used in various power transmission systems, including conveyor systems, automotive assembly lines, industrial machinery, and more. They can accommodate different loads, speeds, and operating conditions.

6. Durability and Longevity: Motor chains are designed to withstand heavy-duty applications and harsh operating environments. They are made from high-quality materials, such as alloy steel, that provide excellent strength, wear resistance, and durability, ensuring a long service life.

7. Easy Maintenance: Motor chains typically require minimal maintenance. Regular lubrication and periodic inspection are usually sufficient to keep them in optimal operating condition. This ease of maintenance contributes to the overall cost-effectiveness of using motor chains.

Overall, using a motor chain in power transmission systems offers reliable and efficient power transfer, precise speed control, versatility, and long-term durability. These advantages make motor chains a popular choice in various industries for transmitting power from motors to driven equipment.

What is a motor chain and how is it used?

A motor chain, also known as a power transmission chain, is a mechanical device used to transmit power from a motor or engine to various parts of a machine or system. It consists of a series of interconnected links that form a flexible and durable chain.

Motor chains are commonly used in a wide range of applications, including automotive, industrial machinery, agricultural equipment, and conveyor systems. They play a vital role in transmitting rotational motion and power from the motor to different components such as wheels, gears, sprockets, or pulleys.

Here’s how a motor chain is typically used:

1. Power Transmission: The primary function of a motor chain is to transmit power from the motor to other parts of the system. When the motor rotates, it drives the chain, which in turn drives the connected components, enabling them to perform their intended functions.

2. Speed and Torque Conversion: Motor chains are designed to transmit power at different speeds and convert the torque between the motor and the driven components. By selecting appropriate sprocket sizes and chain lengths, the rotational speed and torque can be adjusted to suit the requirements of the system.

3. Flexibility and Adaptability: Motor chains are flexible and adaptable, allowing them to be used in various orientations and configurations. They can accommodate misalignment, uneven loads, and changes in direction, making them suitable for complex machinery and systems.

4. Maintenance and Lubrication: Proper maintenance and lubrication are essential for the reliable operation of motor chains. Regular inspection, cleaning, and lubrication help reduce friction, wear, and corrosion, ensuring optimal performance and longevity of the chain.

Motor chains come in different sizes, designs, and materials to suit specific applications. Selecting the right chain for a particular system involves considering factors such as load capacity, speed, environment, and compatibility with other components. It is important to follow the manufacturer’s guidelines and industry standards to ensure safe and efficient operation.

editor by CX 2023-08-18