Product Description

ZHangZhoug CHINAMFG Machinery Co., Ltd

(DIN/ANSI/JIS Standard or made to drawing)

Product Description:

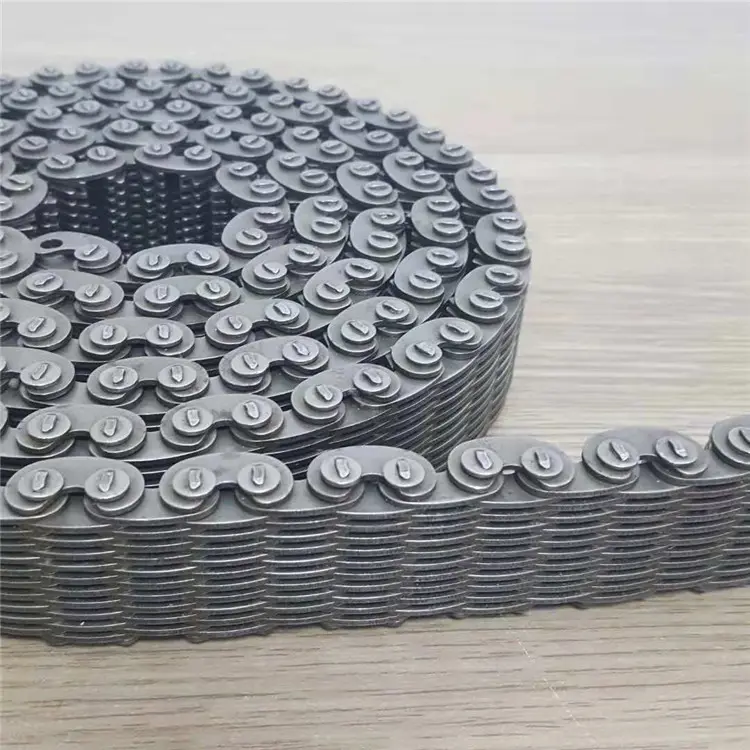

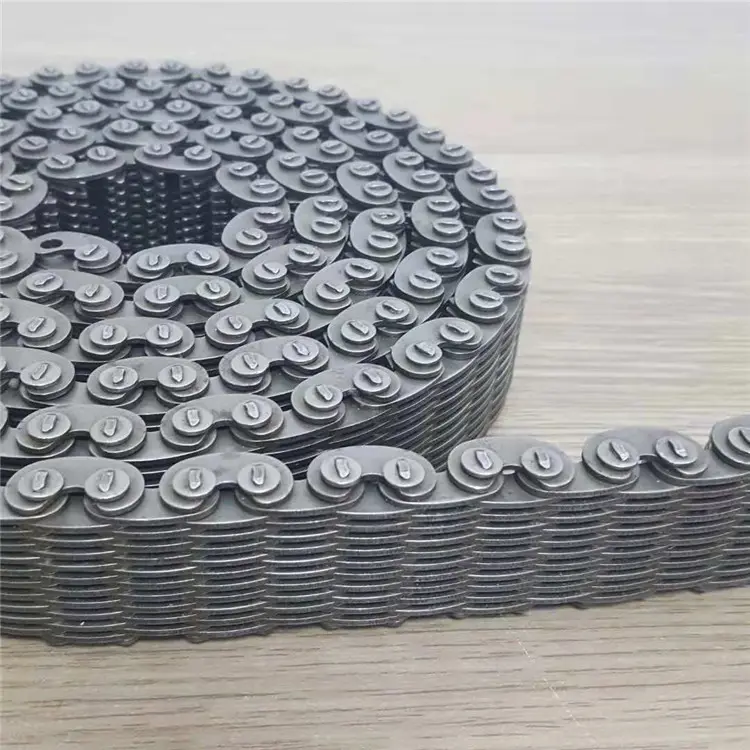

Detailed Photos:

Company Profile:

ZHangZhoug CHINAMFG Machinery Co., Ltd. Is the vice chairman of chain Transmission Branch of China Machinery General parts Industry Association and a member of China chain Transmission Standardization Technical Committee.

Founded in 1954, mainly engaged in sprocket, gear, timing belt pulley, coupling production and sales, It is a large sprocket manufacturing enterprise in China, and it is also 1 of the largest standard sprocket manufacturers in the world at present. The product structure of the company has been developed from the single pattern of standard sprocket to non-standard transmission parts. Products are mainly sold in North America, South America, Europe, Africa and Japan, South Korea, the Middle East, Russia and Southeast Asia and other countries and regions, sales network all over the world.

The company has passed ISO 9002 quality assurance system certification for the first time in 1999, ISO9001: 2000 quality management system certification in 2003, ISO/TS16949 quality management system certification for the first time in 2009, ISO14001: 2004 environmental management system certification for the first time in 2571, ISO14001: 2015 environmental management system certification for 2017, and ISO9001: 2015 and IATF16949: 2016 quality management system certification for 2018. It lays a CHINAMFG foundation for perfecting the internal management of the enterprise and opening up the external market.

The company adheres to the business philosophy of “Quality is life, technology is physique, delivery is moral, quantity is credit, service is kindred, cost is lifetime”, implementing “innovation-driven, twinning integration” upgrading strategy, promoting chain transmission products to excellence, and making every effort to create “harmonious cenfit, good quality cenfit, hundred years of cenfit”

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Machinery, Agricultural Machinery, Car |

| Hardness: | Hardened Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

What is a motor chain and how is it used?

A motor chain, also known as a power transmission chain, is a mechanical device used to transmit power from a motor or engine to various parts of a machine or system. It consists of a series of interconnected links that form a flexible and durable chain.

Motor chains are commonly used in a wide range of applications, including automotive, industrial machinery, agricultural equipment, and conveyor systems. They play a vital role in transmitting rotational motion and power from the motor to different components such as wheels, gears, sprockets, or pulleys.

Here’s how a motor chain is typically used:

1. Power Transmission: The primary function of a motor chain is to transmit power from the motor to other parts of the system. When the motor rotates, it drives the chain, which in turn drives the connected components, enabling them to perform their intended functions.

2. Speed and Torque Conversion: Motor chains are designed to transmit power at different speeds and convert the torque between the motor and the driven components. By selecting appropriate sprocket sizes and chain lengths, the rotational speed and torque can be adjusted to suit the requirements of the system.

3. Flexibility and Adaptability: Motor chains are flexible and adaptable, allowing them to be used in various orientations and configurations. They can accommodate misalignment, uneven loads, and changes in direction, making them suitable for complex machinery and systems.

4. Maintenance and Lubrication: Proper maintenance and lubrication are essential for the reliable operation of motor chains. Regular inspection, cleaning, and lubrication help reduce friction, wear, and corrosion, ensuring optimal performance and longevity of the chain.

Motor chains come in different sizes, designs, and materials to suit specific applications. Selecting the right chain for a particular system involves considering factors such as load capacity, speed, environment, and compatibility with other components. It is important to follow the manufacturer’s guidelines and industry standards to ensure safe and efficient operation.

editor by CX 2023-11-30