Product Description

1. This machine is used to transfer upper mold transversely.

2. Control System: Electrical part needs to be connected to the power of 380V/50Hz.

| Product name | specification |

| #2242 | length 2242mm |

| #4222 | length 4222mm |

| #5212 | length 5212mm |

| #6202 | length 6202mm |

| #3232 | length 3232mm |

* The length of conveyor can be produce according to design.

ZheJiang Tang Chen Machinery Equipments Manufacturing Co., Ltd. is Founded in 2011 with registed capital of 25,000,000 CNY, covering a total area of 13.34 hectare including 43000 square meter workshop.

The company mainly focuses on the R&D, production and sales of the mould & equipment for precast concrete elements, especially for concrete spun pile and spun pole.

Instead of only supplying machinery, we provide integrated solution with value added service, so that customers can easily start production by simply turning the key.

Currently the company have exported to Korea, Vietnam, Malaysia, Bangladesh, Cambodia and Indonesia. And have successfully built more than 10 overseas projects.

We are confident we will always be the right choice for you!

CHINAMFG can provide profecssional concrete production line.

step 1 raw material mixing & steel bar cage making

step 2 cage placing & concrete feeding

step 3 stressing

step 4 centrifugal spinning

step 4 steam curing

step 5 demoulding

step 6 high pressure curing

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Transport Machinery |

| Shotcrete Type: | OEM |

| Machining Process: | Processing, Welding, Paiting |

| Structure: | Electrical Motor |

| Customization: |

Available

| Customized Request |

|---|

Can a motor chain be used in environments with high temperatures or humidity?

Yes, motor chains can be used in environments with high temperatures or humidity, but certain considerations need to be taken into account.

High Temperatures:

When operating in high-temperature environments, it is important to choose a motor chain that can withstand the elevated temperatures. Special heat-resistant materials, such as heat-treated steel or alloys, are often used for the construction of chains intended for high-temperature applications. These materials have superior heat resistance and can maintain their strength and performance even at elevated temperatures.

In addition to selecting the appropriate chain material, proper lubrication becomes even more critical in high-temperature environments. The lubricant used should have a high temperature rating to ensure adequate lubrication and prevent premature wear. Regular monitoring of the chain’s condition and lubrication levels is essential to maintain its performance and minimize the effects of heat.

Humidity:

In humid environments, the risk of corrosion and rust formation on the motor chain increases. To address this, corrosion-resistant materials and coatings are commonly used for motor chains. Stainless steel chains or chains with special corrosion-resistant coatings provide better protection against moisture and humidity.

Proper maintenance and lubrication are also crucial in humid environments to prevent moisture from penetrating the chain and causing corrosion. Regular inspections, cleaning, and lubrication with corrosion-inhibiting lubricants can help extend the lifespan of the chain and maintain its performance.

It is important to note that while motor chains can be used in high-temperature or humid environments, their performance and lifespan can still be affected. It is recommended to consult the chain manufacturer for specific guidelines and recommendations regarding the use of motor chains in such conditions. Additionally, proper ventilation and environmental controls should be considered to minimize the impact of high temperatures or humidity on the chain’s performance.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

What are the different types of motor chains available?

Motor chains come in various types, each designed to meet specific requirements of different applications. Here are some common types of motor chains:

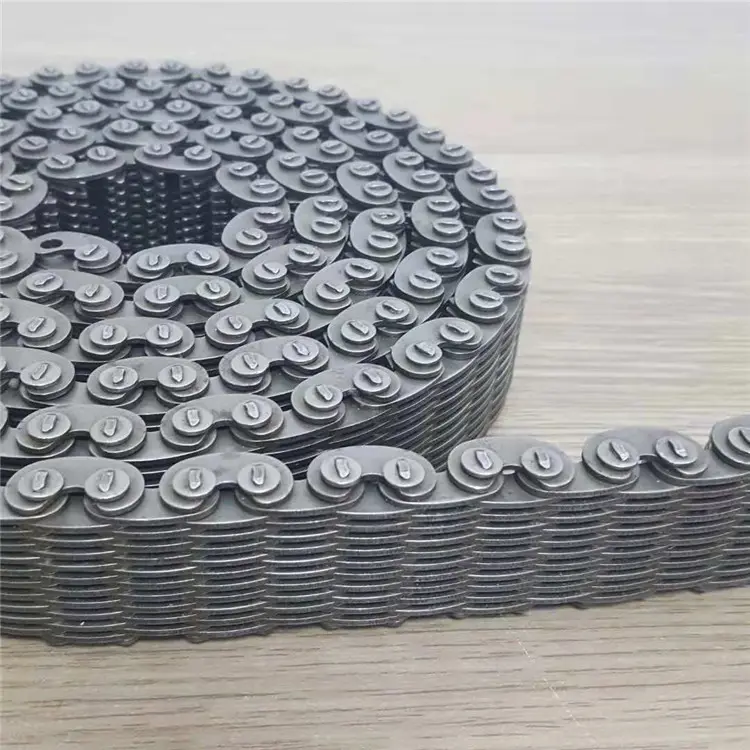

1. Roller Chains: Roller chains are the most common type of motor chain. They consist of inner and outer plates connected by rollers. These chains are known for their high strength, durability, and ability to handle heavy loads. Roller chains are widely used in industries such as automotive, industrial machinery, and agriculture.

2. Silent Chains: Silent chains, also known as inverted-tooth chains, feature tooth-shaped plates that engage with each other. They provide smooth and quiet operation, making them suitable for applications requiring low noise levels. Silent chains are commonly used in precision machinery, printing presses, and automotive timing systems.

3. Leaf Chains: Leaf chains have flat, interlocking plates connected by pins. They are primarily used in lifting and hoisting applications, such as forklifts and cranes. Leaf chains are known for their high tensile strength and resistance to fatigue.

4. Conveyor Chains: Conveyor chains are specifically designed for conveying materials in conveyor systems. They feature large, wide plates to support the load and provide smooth movement. Conveyor chains are used in industries such as mining, food processing, and packaging.

5. Timing Chains: Timing chains are used in engines to synchronize the rotation of the crankshaft and camshaft. They have precise tooth profiles that ensure accurate timing of valve operation. Timing chains are commonly found in automotive engines and other internal combustion engines.

6. Specialty Chains: There are also specialized motor chains designed for specific applications. Examples include escalator chains, bicycle chains, motorcycle chains, and marine chains.

Motor chains are available in different sizes, materials, and configurations to suit specific requirements. It is important to select the appropriate chain type based on factors such as load capacity, speed, environment, and application-specific needs.

editor by CX 2024-05-07